- Coal handling

- Coke production

- By-product recovery plants

- General layout and transport

- 3D plan development

- Architecture and construction

- Heat-and-power engineering

- Electrical engineering

- Automated control systems

- Atmospheric air protection

- Water environment protection

- Processing of carbon-containing feed

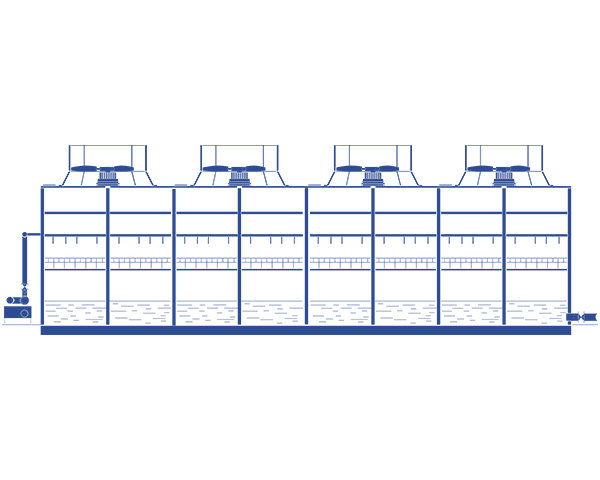

Water environment protection

For protection of water bodies against pollution by waste waters GIPROKOKS provides the following: Division of sewerage systems by sources of their formation (rainwater, sludge, utility, phenolic). Unit for sludge waters treatment for system of wet dust cleaning and hydraulic cleaning. Unit for mechanical and biochemical treatment of industrial phenolic waste waters with utilization of treated waste waters on the territory of coke oven and by-product enterprises.

Details

Processing of carbon-containing feed

Alternative technologies for using feedstock containing carbon Contemporary economic challenges: Insufficient production of oil and gas condensate. Necessity to ensure rational and effective usage of natural resources. Unstable prices for oil and motor fuel. Insufficient quality of domestically produced motor fuel. Environmental problems of the conventional usage of hard coal fuel. Depleting potential of conventional technologies for the production of motor fuel.

Details

3D plan development

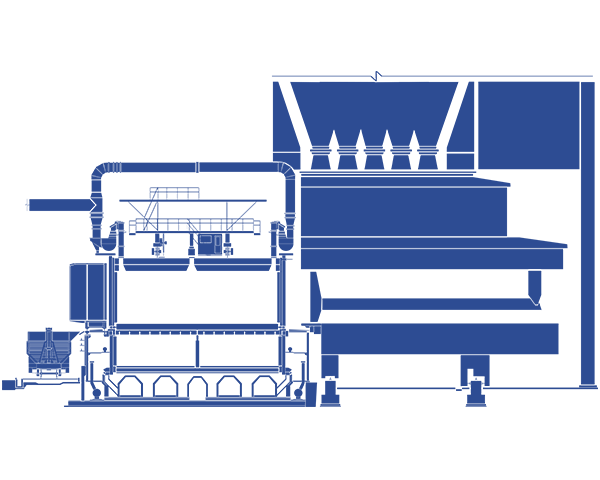

DetailsCoal handling

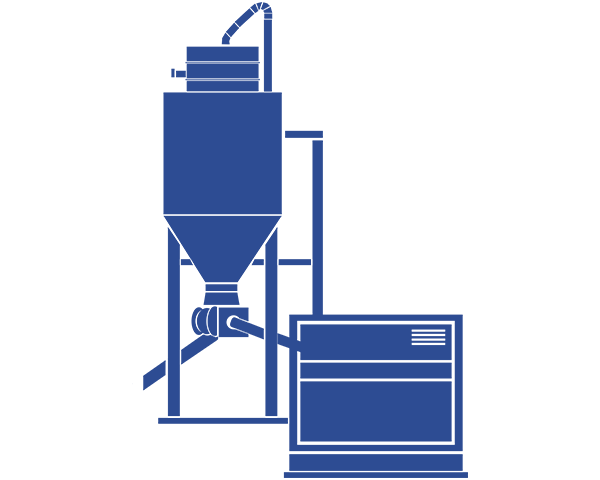

GIPROKOKS performs complex design and engineering activities for conventional sequence of coal blend handling for carbonization: receipt, de-freezing, preliminary crushing, stocking, proportioning of coals, supply of coke oven and by product production wastes to coal blend, finishing grinding, mixing and transportation of coal blend to coal tower

Details

Architecture and construction

All technologies and concepts for subsequent construction work are specified taking into account the current rules and regulations: local, construction, climatic, functional, engineering, technological, fire-fighting, sanitary-hygienic, ecological, and also economic requirements of the Customer.

Details

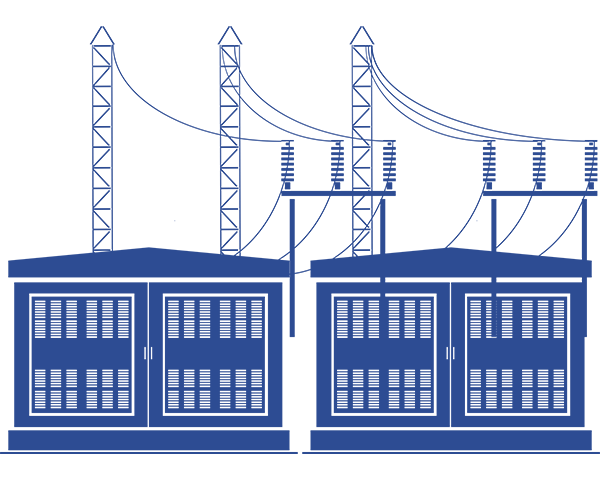

Electrical engineering

GIPROKOKS elaborates electrical engineering part of design documentation for major construction, reconstruction and major repair of technological facilities and power supply facilities of coke oven and by-product enterprises.

Details

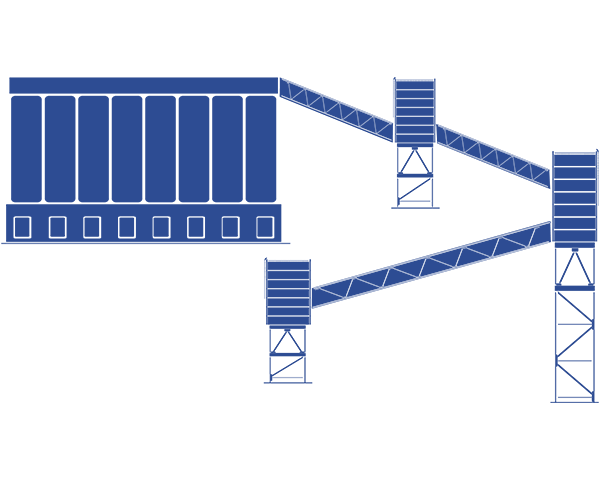

General layout and transport

This is an engineering document which solves a set of issues related to management of territory for construction: leveling; building; reconstruction; lanscaping.

Details

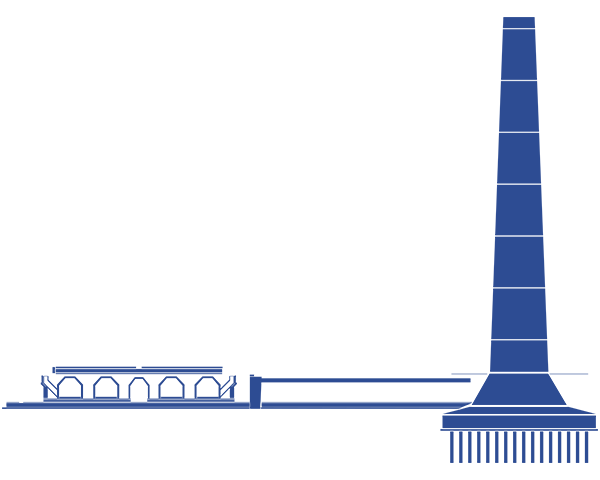

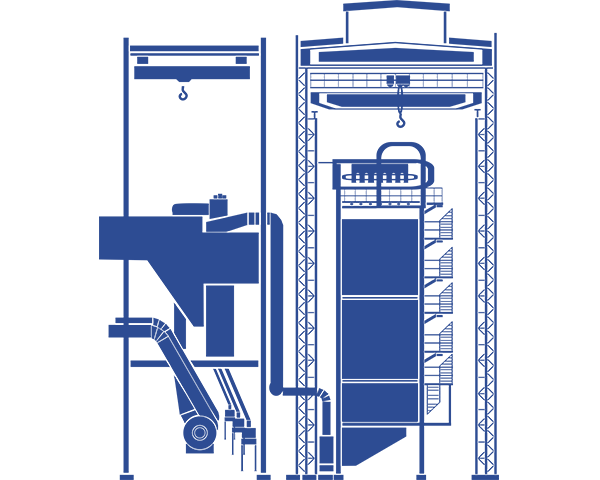

Coke production

GIPROKOKS executes complex designing of coke oven plant facilities: coke oven batteries for production of blast furnace and foundry coke; ovens for production of special kinds of coke; pushing emission control systems; coke dry cooling plants; coke wet quenching complexes; coke transportation, handling, screening, uploading and storage facilities; coal towers; garages for repair of coke oven machines; hangars for erection of coke oven batteries brickwork; refractories, materials and equipment storage.

Details

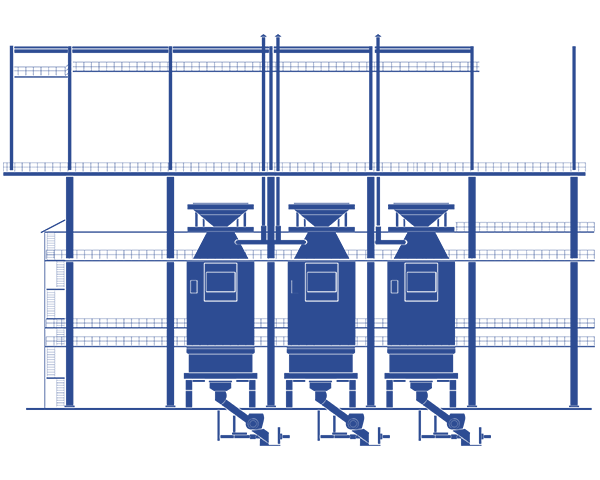

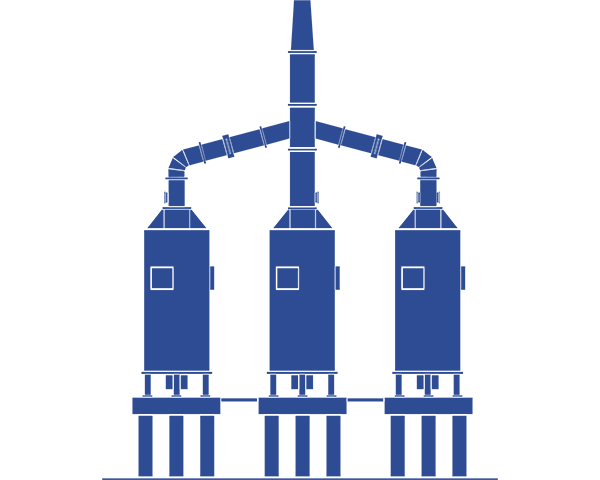

Coke dry cooling plant

GIPROKOKS is the founder of state-of-the-art technology of coke dry cooling. The widespread tightening of environmental standards and the need to introduce energy-saving technologies of high quality coke production alongside the deterioration of coking coal feedstock base predetermine the priority of coke dry cooling for the near future.

Details

Coke oven batteries for carbonization of stamped coal blend

GIPROKOKS has successfully implemented the technology of preliminary stamping (coal blend stamping) which is increasingly used to produce coke from coal blends with an increased content of lean-caking coals up to 65% (conventional technology provides up to 35%). The essence of the process is the compaction of coal grains during stamping. This assists to improve coking of coal during carbonization and to produce coke of high mechanical strength.

Details

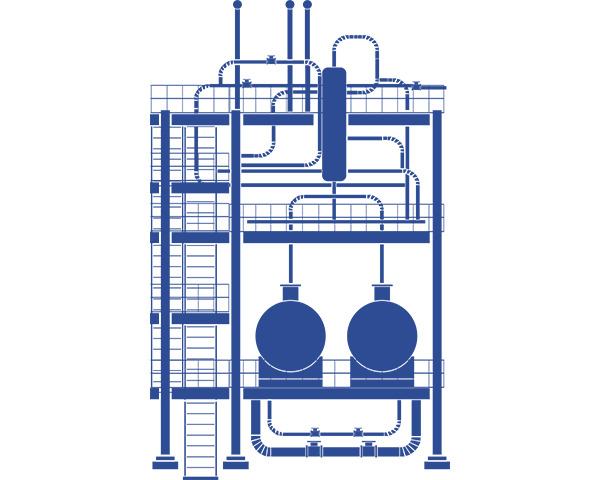

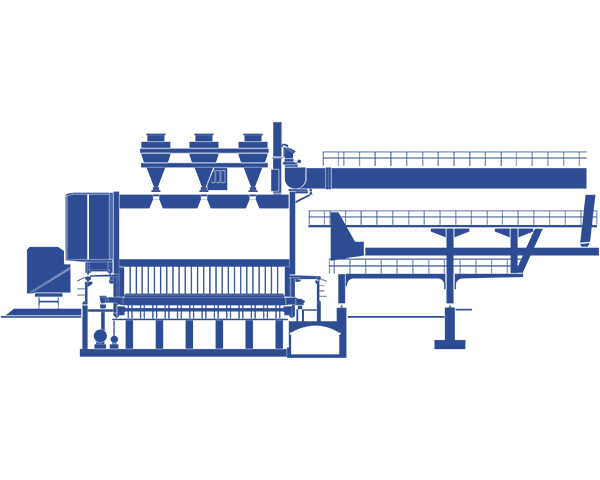

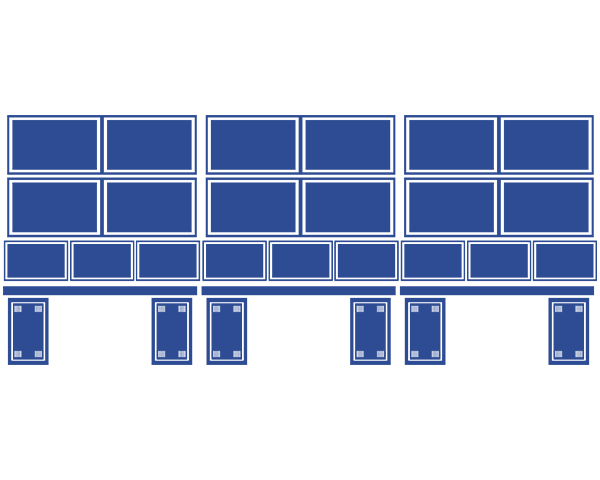

By-product recovery plants

Main design facilities: By-product recovery plant. The plants of hydrogen sulfide recovery from coke oven gas to produce sulfuric acid or sulfur. Crude benzene processing plants. Tar processing plants. Various binders preparation units. Tank batteries for liquid products. Storages for bulk products storing, packaging and loading. Coke oven gas fine purification units for long-distance gas transportation. Central plant laboratories. Liquid waste products utilization unit. Systems of by-product plants' equipment sealing. Fuel production units, including motor fuel, from coal and other raw materials. Technical projects of individually manufactured equipment.

Details

Heat-and-power engineering

Production of steam with various parameters and highly efficient generation of electric energy due to using secondary energy resources from iron & steel making plants, coke oven and by-product recovery plants as well as fossil fuels: Selection of optimal system for co-generation of steam and electric power on the basis of common heat and gas balance of production plant. Ensuring low prime cost of the generated steam and electric power due to using secondary energy resources. Using up-to-date equipment from the leading manufacturers (boilers and steam turbines of individual manufacture, gas turbines, gas reciprocating engines, etc.).

Details

Automated control systems

Following the policy of the uniformity between technology and automation of processes GIPROKOKS performs projects for creation and modernization of systems for automated control and management of technological processes using up-to-date equipment and software, accumulated experience of their implementation and continuous operation: Coke oven batteries. Coke dry cooling plants. By-product recovery plants. Associated facilities of coke oven and by-product plants.

Details

Atmospheric air protection

GIPROKOKS offers the following main technical solutions:

Elaboration and improvement of technological processes that allow to minimize negative impact upon environment.

Systems of dry coke cooling and complexes of wet coke quenching with improved design that reduce emissions of harmful substances into atmosphere.

Aspiration systems with single and two-stage cleaning of aspiration air with implementation of BAT-technologies.

Details

.png)